As late spring transitions into early summer, and the landscape bursts with lush greenery, Megasteel's sites bustle with activity! The "Megasteel Sightseeing Tour" warmly

invites you to visit our construction sites. Keep this "sightseeing guide" handy for a safe visit. We hope you enjoyevery moment.

Megasteel's team ensures hoisting safety through meticulous pre-operation preparations:

• Pre-draft detailed lifting plans with site-specific risk assessments.

• Conduct pre-work safety & technical briefings for all construction personnel.

• Performance comprehensive inspections and acceptance of lifting equipment and tools.

• Validate that hoisting gears and ropes comply with safety specifications prior to use.

• Execute precise crane operations under certified signal command.

• Position beams and columns steadily in their designated positions.

Tips:

Thoroughly check lifting equipment and ropes for any defects or wear before starting. Fasten loads securely to prevent sliding or shifting, and always ensure the center of gravity is balanced. Pre-plan the lifting path and keep all non-essential personnel at a safe distance from the operation area. Use clear, standardized signals, lift and lower loads slowly and steadily to ensure safety.

Megasteel constructs a robust safety protection system through technological innovation:

Systematic Equipment Deployment: Undertake rational equipment selection, rigorous load calculations, and thorough installation inspections to lay a solid foundation.

Lifeline System Innovation: Pioneering use of X-shaped and arc-shaped lifeline systems ensures full coverage of aerial work areas, giving workers "ropes to cling to and nets to fall back on." Translate safety standards into tangible safeguards, making invisible norms into visible protective barriers.

Structural Safety Solutions: Employ frame-type composite access walkways, mechanically validated for high load-bearing capacity and stability, with non-slip pedals to create a "safety ladder" for personnel movement.

Efficiency-transfer Tools: Independently developed lifting and transfer beams optimize center-of-gravity design, reducing hoisting time while minimizing personnel directly contact risks.

Tips:

Ensure full coverage of aerial safety nets and fasten hooks securely for peace of mind. Stable access walkways guide every safe step, while non-slip pedals protect your journey

from start to finish. Transfer beams cleverly distribute weights, balancing the center of gravity boosts both efficiency and safety. Conduct daily equipment inspections to ensure safe operations.

Megasteel carefully considers the environmental conditions of the site through meticulous attention to detail:

Dust Control Elegance: Tower crane sprinklers create floating water curtains, while water trucks paint dust on hardened roads.Noise Mitigation: Select low-noise construction

equipment with real-time noise monitoring ensures construction proceeds without disturbing the peace.

Cleanliness as Standard: Establish an immediate waste-clearing mechanism, maintaining a "picture-perfect" environment at all times.

Daily waste clearance keeps the site clean; sprinkling reduces dust for fresh air. Regular maintenance of machinery ensures low-noise operation and high efficiency. Soundproof barriers build a protective wall for minimizing disturbance and fostering positive relationships with surrounding neighborhoods.

Double-driven energy conservation and environmental protection showcase civilized sites.

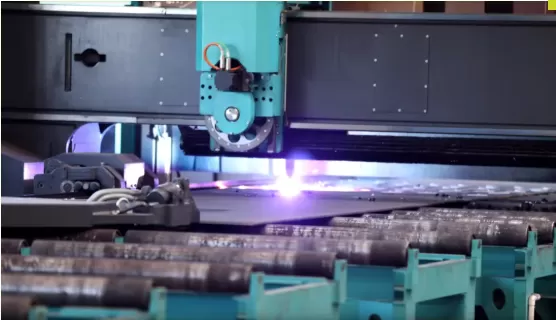

In Megasteel's intelligent factory, safety and efficiency converge seamlessly:

Perimeter Security Redefined: Standardized security fences integrated with infrared alarm systems form safety protection networks, ensuring unauthorized access is instantly detected.

Digital-Driven Production: Intelligent manufacturing processes minimize manual intervention, reducing human error and enhancing operational precision. Digital management systems streamline workflow coordination, cutting downtime and boosting productivity.

Sustainability in Action: Imported advanced welding fume dust removal systems and VOCs treatment equipment, making dust "nowhere to hide." Environmental standards far exceed local industry requirements.

Tips:

Cutting and welding dust removal devices makes pollution invisible, welding soundproofing reduces welding noise, creating eco-friendly operations that prioritize worker comfort. Moisture-proof material storage with proper ventilation management, optimizing resource longevity.

Waste recycling programs achieve material reuse, turning green factory initiatives into measurable sustainability triumphs.

Warmly Reminder

Keep these tour tips, safety awareness is the most precious "souvenir" of your visit. Megasteel always builds quality with ingenuity, and safeguards the peace of countless homes. Looking forward to meeting you again, to create more wonderful moments together.